Introduction

There’s something magical about taking a stock vehicle and transforming it into a fire-breathing beast with your own two hands. The aftermarket performance industry has come a long way since the days of sketchy mail-order parts and backyard engineering.

Today, we have access to precision-engineered components that can squeeze every last ounce of power from our engines while maintaining reliability.

In this comprehensive guide, I’ll share my hard-earned knowledge and experiences to help you navigate the exciting world of DIY performance upgrades. We’ll cover everything from engine modifications to suspension tuning, weight reduction, and even the future of electric performance.

So grab a wrench, and let’s dive in!

Engine Upgrades: The Heart of Performance

Forced Induction: Boost Done Right

Forced induction is often the go-to for massive power gains, but there’s more to it than just bolting on a turbo and calling it a day. The key comes from understanding the delicate balance between boost, fuel, and timing.

When I first started experimenting with turbochargers, I made the rookie mistake of cranking up the boost without properly addressing fuel delivery and ignition timing. The result?

A spectacular engine failure that taught me a valuable lesson: forced induction requires a holistic approach.

To successfully apply a forced induction system, consider the following:

- Boost control: Invest in a quality boost controller to manage pressure precisely.

- Fuel system upgrades: Larger injectors, high-flow fuel pumps, and upgraded fuel pressure regulators are essential for feeding a hungry turbocharged or supercharged engine.

- Intercooling: An effective intercooler is crucial for keeping intake temperatures in check and preventing detonation.

- Engine management: A standalone ECU or quality piggyback system is necessary for fine-tuning fuel and ignition maps.

- Supporting modifications: Upgraded internals like forged pistons and connecting rods may be necessary for high-boost applications.

Naturally Aspirated Power: Breathing Easy

While forced induction offers massive power gains, there’s something to be said for the linear power delivery and reliability of a well-built naturally aspirated engine. Here are some key areas to focus on:

- Intake systems: A high-flow cold air intake can provide noticeable gains, especially when paired with other modifications.

- Exhaust upgrades: Headers, high-flow catalytic converters, and a free-flowing exhaust system can help your engine breathe easier.

- Camshafts: Aftermarket camshafts can dramatically alter your engine’s power curve, but choose wisely based on your goals and driving style.

- Cylinder head work: Porting and polishing, along with larger valves, can significantly improve airflow.

- Compression ratio: Increasing compression can boost power, but be mindful of fuel quality requirements.

The Importance of Proper Tuning

No matter what engine modifications you choose, proper tuning is absolutely critical. I’ve seen countless engines go up in smoke because their owners didn’t grasp the importance of dialing in the fuel and ignition maps.

Invest in a quality tuning solution, whether it’s a standalone ECU, a piggyback system, or professional dyno tuning. Take the time to learn about air/fuel ratios, ignition timing, and how different modifications affect these parameters.

Your engine will thank you with reliable power and longevity.

Fuel System Upgrades: Feeding the Beast

A robust fuel system is the underestimated pillar of any high-performance build. Your stock injectors and pump might be fine for a mild bump in power, but push things too far, and you’ll find yourself running dangerously lean.

I learned this lesson the hard way when I melted a piston in my first turbo build. Now, I always make sure to upgrade the entire fuel system before cranking up the boost.

Here’s what you need to consider:

- Fuel injectors: Choose injectors sized appropriately for your power goals, taking into account duty cycle and fuel pressure.

- Fuel pump: A high-flow in-tank or external fuel pump is essential for maintaining proper fuel pressure under high demand.

- Fuel pressure regulator: An adjustable fuel pressure regulator allows for fine-tuning and compensating for increased fuel demand.

- Fuel lines and fittings: Don’t neglect the plumbing!

Upgrade to larger diameter fuel lines and high-quality fittings to ensure adequate flow.

- Fuel rail: A larger fuel rail can help maintain consistent pressure across all injectors.

Remember, a well-designed fuel system should have some headroom beyond your current power goals. This allows for future upgrades without immediately maxing out your fuel delivery capabilities.

Suspension Upgrades: Putting Power to the Ground

A well-sorted suspension can transform a car’s handling, making it feel like it’s on rails through the corners. However, there’s a fine line between performance and comfort.

I’ve driven cars that were absolute monsters on the track but unbearable on the street.

The key is finding the right balance for your specific needs.

Coilovers vs. Lowering Springs

Coilovers offer the most adjustability, allowing you to fine-tune ride height, spring rates, and damping. They’re ideal for track-focused builds or those who want maximum control over their suspension setup.

However, quality coilovers can be expensive, and the adjustability can be overwhelming for beginners.

Lowering springs, on the other hand, offer a simpler and more affordable way to improve handling and aesthetics. They’re a great choice for street-driven cars that see occasional track use.

Just be sure to pair them with appropriate shocks to maintain proper damping.

Sway Bars and Chassis Bracing

Upgrading sway bars (anti-roll bars) can dramatically reduce body roll and improve turn-in response. Adjustable sway bars allow you to fine-tune the balance between understeer and oversteer.

Chassis bracing, such as strut tower braces and underbody braces, can increase overall chassis rigidity. This results in improved handling and a more connected feel between the driver and the road.

Alignment and Geometry

Don’t overlook the importance of proper alignment and suspension geometry. Adjustable control arms, camber plates, and toe arms allow you to dial in your alignment for optimal performance.

A professional alignment, preferably with someone experienced in performance setups, can make a world of difference in how your car handles.

Weight Reduction: The Importance of Less

Weight reduction is often overlooked in favor of flashy power adders, but shedding pounds can have a dramatic effect on your car’s performance. I once helped a friend strip over 300 pounds from his track car, and the difference in lap times was staggering.

Here are some areas to focus on for effective weight reduction:

- Interior: Remove unnecessary seats, carpets, sound deadening, and trim pieces.

- Glass: Replace side and rear windows with lightweight polycarbonate.

- Body panels: Swap heavy steel panels for fiberglass or carbon fiber alternatives.

- Wheels: Lightweight wheels can significantly reduce unsprung weight.

- Battery: Replace the stock battery with a lightweight racing battery or relocate it to the trunk for better weight distribution.

- Exhaust: A lightweight exhaust system can shave significant weight, especially on older vehicles with heavy cast iron manifolds.

Just remember, there’s a point of diminishing returns – you don’t want to compromise safety or structural integrity if you’re targeting lightness. Always consider the impact on daily drivability if you’re building a dual-purpose street/track car.

Emissions Compliance: Performance Meets Legality

With regulations getting stricter every year, it’s becoming increasingly challenging to build high-performance cars that can still pass smog checks. But fear not, there are ways to have your cake and eat it too.

High-Flow Catalytic Converters

Catalytic converters have come a long way, and modern high-flow cats can offer significant performance gains while keeping your car legal. Look for CARB-certified catalytic converters that are legal for use in all 50 states.

ECU Tuning and Emissions Readiness

Many modern engine management systems allow for separate tunes – one for performance and one for emissions testing. Just be sure your ECU can quickly switch between tunes and set all emissions readiness watches before heading to the testing station.

OBD-II Compliant Modifications

When choosing aftermarket parts, look for those that are specifically designed to work with your vehicle’s OBD-II system. This helps ensure that all sensors and emissions equipment function properly, reducing the likelihood of check engine lights or failed emissions tests.

The Rise of Electric Performance

One of the most exciting developments in recent years has been the rise of electric and hybrid performance. We’re seeing incredible advancements in battery technology and electric motors that are giving traditional combustion engines a run for their money.

I recently drove a Tesla Model S Plaid, and the instant torque delivery was mind-blowing. It’s clear that the future of performance is electrified, and I can’t wait to see what innovations come next.

Electric Conversions

For DIY enthusiasts, electric conversions of classic cars are becoming increasingly popular. With the availability of aftermarket electric motors, battery systems, and controllers, it’s now possible to breathe new life into old vehicles while embracing cutting-edge technology.

Hybrid Performance

Hybrid systems are no longer just about fuel economy. Performance hybrids like the Acura NSX and Porsche 918 Spyder show how electric motors can complement traditional engines, providing instant torque fill and improved overall performance.

The DIY Performance Community

For those of us who prefer to wrench on our own rides, the DIY performance scene has never been more accessible. Online communities and forums are treasure troves of information, allowing enthusiasts to share knowledge and troubleshoot issues.

However, it’s crucial to approach these resources with a critical eye. Not all advice is created equal, and what works for one person’s build might be disastrous for another’s.

Always cross-reference information from many sources and, when in doubt, ask with professionals or experienced builders.

Proper Preparation and Installation

When it comes to actually installing performance parts, proper preparation is key. I always start by thoroughly cleaning my workspace and gathering all the necessary tools before I even think about turning a wrench.

There’s nothing worse than being elbow-deep in an engine bay and realizing you’re missing a crucial socket or gasket.

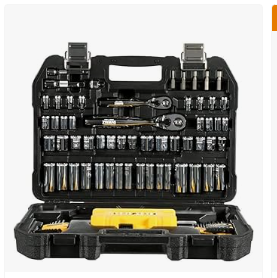

Essential Tools for DIY Performance Upgrades

- Quality socket set with various extensions and universal joints

- Torque wrench for proper fastener tightening

- Multimeter for electrical diagnostics

- OBD-II scanner for reading and clearing codes

- Jack stands and a reliable floor jack for safely lifting your vehicle

- Specialty tools specific to your make and model (e.g., timing belt tools, pulley holders)

The Importance of Proper Torque Specs

Always use a torque wrench and follow manufacturer-specified torque values when installing critical components. Over-tightening can lead to stripped threads or broken fasteners, while under-tightening can result in leaks or parts working loose over time.

Troubleshooting and Diagnostics

One of the biggest challenges in DIY performance upgrades is diagnosing issues when things don’t go as planned. A good diagnostic scanner is worth it’s weight in gold, allowing you to read and clear error codes quickly. But beyond that, developing a systematic approach to troubleshooting is essential.

I always start with the basics – fuel, air, and spark – before diving into more complex systems. Here’s a simple troubleshooting checklist I use:

- Check for obvious issues: loose connections, vacuum leaks, or visible damage

- Scan for error codes and research their meanings

- Verify fuel pressure and injector operation

- Check ignition system components (spark plugs, coils, wires)

- Inspect air intake system for leaks or restrictions

- Monitor live data (if available) to identify abnormal sensor readings

- Perform compression and leak-down tests if engine performance is suspect

Remember, patience is key when diagnosing issues. Resist the urge to throw parts at a problem without first identifying the root cause.

Warranty Considerations

One aspect of performance upgrades that often gets overlooked is the impact on your car’s warranty. Many manufacturers will void your warranty if they detect aftermarket modifications.

However, there are ways to navigate this minefield.

Familiarize yourself with the Magnuson-Moss Warranty Act, which protects consumers’ rights to use aftermarket parts without automatically voiding their warranty. The key is understanding that the manufacturer must prove that your modification caused the failure in question.

To protect yourself:

- Keep detailed records of all modifications and maintenance

- Use high-quality, reputable parts from established manufacturers

- Consider removable modifications that can be reverted to stock if warranty work is needed

- Be upfront with your dealership about modifications – some are more mod-friendly than others

Heat Management: The Silent Performance Killer

As we push our vehicles to their limits, heat management becomes increasingly critical. I’ve seen too many builds fall victim to heat soak and thermal breakdown.

Investing in proper cooling systems, heat shielding, and thermal management solutions can mean the difference between a reliable powerhouse and a ticking time bomb.

Cooling System Upgrades

- High-capacity radiator

- Electric fans with proper controls

- Silicone hoses and high-pressure radiator cap

- Water pump upgrade (if available for your application)

- Engine oil cooler for high-performance or track-driven vehicles

Heat Shielding

Proper use of heat shielding can protect sensitive components and reduce under-hood temperatures. Consider heat-wrapping exhaust components and using reflective heat barriers around the intake and fuel system.

Thermal Coatings

Ceramic thermal coatings on exhaust components can significantly reduce heat radiation, improving underhood temperatures and potentially increasing exhaust flow.

Data Logging and Analysis

For those looking to take their builds to the next level, data logging and analysis can provide invaluable insights. Modern engine management systems allow for incredibly detailed monitoring of various parameters.

By analyzing this data, you can fine-tune your setup for maximum performance and reliability.

Key parameters to monitor include:

- Air/fuel ratios across the RPM range

- Ignition timing and knock retard

- Boost pressure and throttle position

- Intake air temperatures

- Coolant and oil temperatures

- Vehicle speed and acceleration

Many standalone ECUs and some OBD-II interfaces allow for real-time data logging. Spend time learning how to interpret this data – it’s like having a window into your engine’s soul.

Frequently Asked Questions

What’s the best first performance upgrade for my car?

The best first upgrade depends on your specific vehicle and goals. Generally, a high-flow air intake or a cat-back exhaust system can provide noticeable gains without breaking the bank or compromising reliability.

How much horsepower will I gain from a cold air intake?

Horsepower gains from a cold air intake vary widely depending on the vehicle and other modifications. Typically, you can expect anywhere from 5-20 horsepower, with some applications seeing even more significant gains.

Are performance chips worth it?

The effectiveness of performance chips varies greatly. For modern vehicles with complex engine management systems, a quality tuner or ECU reflash is generally more effective than a simple plug-in chip.

How much does it cost to turbocharge a naturally aspirated engine?

The cost of turbocharging an engine can range from $3,000 to $10,000 or more, depending on the quality of components and whether you do the work yourself or hire a professional.

Will performance upgrades void my car’s warranty?

While some modifications can affect your warranty, the Magnuson-Moss Warranty Act protects your right to use aftermarket parts. However, if a modification causes a failure, that specific repair may not be covered.

What’s the difference between a short ram intake and a cold air intake?

A short ram intake is typically shorter and located in the engine bay, while a cold air intake has a longer tube that draws air from outside the engine bay for potentially cooler intake temperatures.

How often should I change the oil in a modified high-performance engine?

Oil change intervals for modified engines are typically shorter than stock. A good rule of thumb is every 3,000-5,000 miles, but this can vary based on your specific build and driving habits.

Can I install coilovers myself?

Installing coilovers is a moderately complex job that requires some mechanical skill and proper tools. While many enthusiasts do it themselves, it’s crucial to follow the instructions carefully and get a professional alignment afterward.

What’s the best way to reduce weight in my car?

Start with removing unnecessary interior components, replacing heavy stock wheels with lightweight choices, and swapping out the battery for a lightweight racing version. More extreme measures include replacing body panels with carbon fiber alternatives.

How do I choose the right size turbocharger for my engine?

Selecting the right turbo involves considering factors like engine displacement, desired power output, and intended use. Consult with turbo manufacturers or experienced tuners to find the best match for your specific application.

Key Takeaways

- Proper tuning and supporting mods are crucial for forced induction setups

- Balance performance with practicality when upgrading suspension

- Weight reduction can yield significant performance gains

- Stay informed about emissions regulations and choose compliant upgrades

- Embrace the future of electric and hybrid performance

- Utilize online communities, but approach advice critically

- Develop systematic troubleshooting skills for when things go wrong

- Consider warranty implications when modifying your vehicle

- Prioritize heat management in high-performance builds

- Use data logging and analysis to fine-tune your setup